5 Key Benefits of Preventive Maintenance for Industrial Vacuum Systems

February 2, 2026

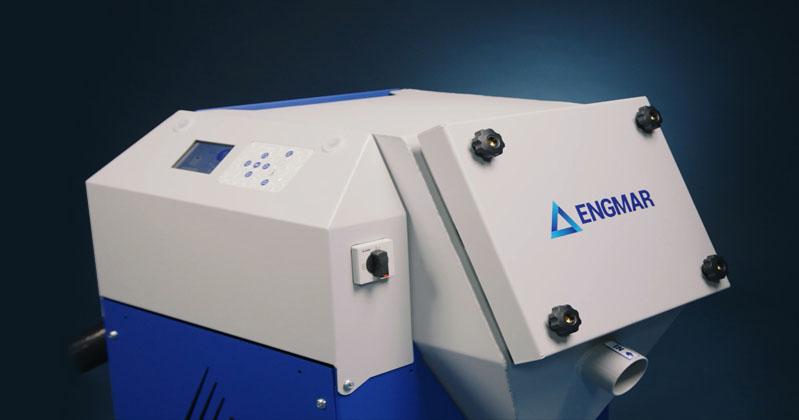

Equipement breakdown often generate production shutdown and high cost for your company. These breakdowns and malfunctions can be anticipated and thus, limited. That’s what preventive maintenance is all about. This aim to anticipate and prevent equipment failures before they compromise productivity. ENGMAR offers you a maintenance service for your high-vacuuum central extraction.

In this article, discover the benefits of preventive maintenance our central extraction.

High security

Installations maintenance and the anticipating accidents linked to malfunctions minimizes health risks for your employees. A company that choose preventive maintenance ensure safety and employee protection against all the risks they may face.

A healthy environment is very important, especially in welding industry. During preventive maintenance of central extraction, numerous tests and checks are carried: installation control and its general operation (cleaning system, extraction speed, filter clogging value record, inspection of cartridges of the filtration unit…). This ensures healthy air in the workshop while optimizing production.

A safety environment encourages employee fulfillment and demonstrates the employers’ commitment to employee health. An important stake even more in welding industry where labor is in high demand.

Cost reduction

Preventive maintenance also allows you to reduce costs of repairs or unexpected parts replaces that can lead to production shutdowns. These production shutdowns can be expensive for the company and block teams from working. Regular replacement of wearing parts increase the lifetime of your installation.

With a preventive maintenance, you ensure the proper functioning of the equipment and of your production rates. Our contrats are quickly paid off and you also benefit from prices that are locked in for 3 years.

The guarantee of safe equipment

Preventive maintenance for ENGMAR industrial central helps extend the life of your installation. Periodic inspection and replacement of minor parts limit the breakdown or breakage of majors parts of LEV system. It also can ensure reliability of your equipment and have a constant production flow. Reducing system shutdowns and breakdown risks can lead to a productivity increase thanks to faster problem solving.

Equipment complying with extraction standards

Purchasing a high-vacuum central extraction system comes with legal obligations. According to the Health and Safety at Work Act 1974 and the Control of Substances Hazardous to Health (COSHH) Regulations 2002 (Ireland: Safety, Health and Welfare at Work Act 2005 and the Safety, Health and Welfare at Work (Chemical Agents) Regulations 2001 to 2021), annual periodic inspections and flow rate measurements are mandatory. These inspections are made to ensure a healthy environment to protect welders and operators from welding fumes. Preventive maintenance ensures that you meet safety standards.

An environmental approach

Preventive maintenance improves installation and equipment lifetime but can also help you save energy and benefit the environment. Indeed, a machine in perfect condition will use less electricity, good news for you bill.

To know more about our maintenance contracts for LEV systems and their rates, contact us.