How to protect welders from Hexavalent Chromium (Chrome VI) in Welding Fumes

January 21, 2026

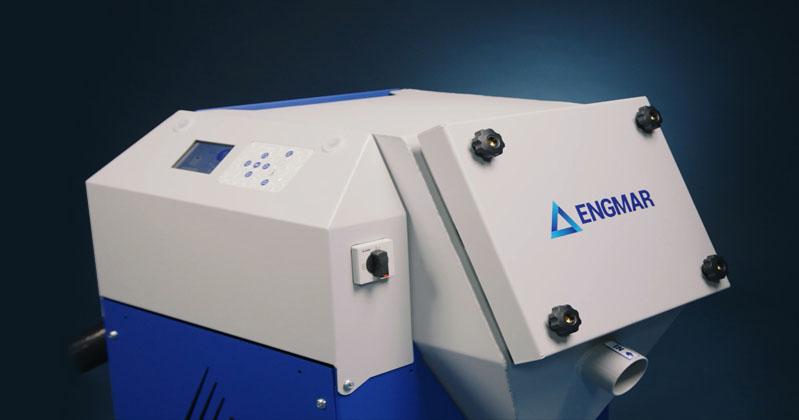

During welding, operators are exposed to many gases and harmful particles, including Hexavalent Chromium, a substance classified as a known carcinogen. To limit risks, an extraction of welding fumes at source is currently the most effective solution. ENGMAR supports industries in implementing efficient extraction systems tailored to each workstation.

How is Chromium VI formed during welding?

Chromium is present in many metal alloys for its corrosion resistance properties. Chromium VI (also known as hexavalent chromium) is an oxidized form of chromium that primarily forms during welding, grinding, or cutting of stainless steel, but also in the case of filler metals containing chromium. This oxidized form is particularly toxic and can cause:

- Bronchial and skin irritations,

- Drying of the respiratory tract,

- Nosebleeds, Metallic taste, Persistent fatigue,

- Increased risk of bronchopulmonary cancers (classified as a certain carcinogen since 1990 – IARC Group 1).

These risks concern all processes, even if the emission levels vary depending on the filler metal and the technique used.

How to reduce welders' exposure to Hexavalent Chromium?

To effectively limit operators' exposure, it is recommended to follow a structured approach with actions to be implemented.

Limit hexavalent chromium emissions by adapting the process and the filler metal

- Choose a less emissive filler metal: a solid wire generates less fumes than a flux-cored wire.

- Adapt the process: TIG welding emits less Hexavalent Chromium than MIG/MAG welding.

2. Extract fumes as close to the welding source as possible

To achieve this, ENGMAR offers solutions to capture harmful gases and pollutants such as Hexavalent Chromium:

• MIG/MAG and TIG Extraction torches: the extraction is directly integrated into the torch to capture toxic particles before they reach the welder's respiratory tract.

Benefits of extraction torches:

- Capture as close as the welding source

- Preserved maneuverability

- Significant reduction of even invisible fumes, especially in stainless steel welding

• Extraction slit nozzle (high-vaccum extraction): when using an extraction torch is not possible, extraction slit nozzle offer an efficient alternative to capture fumes at the source, even in complex configurations.

• General ventilation systems: they complement source capture by extracting and filtering particles remaining in the workshop's ambient air, thus protecting all operators.

For optimal welder protection, a ventilated hood is an excellent PPE to combine with an ENGMAR extraction solution.

Why choose ENGMAR?

Each welding workshop is unique: workstation configuration, level of automation, diversity of parts to be welded, processes used… At ENGMAR, we take into account the needs and constraints of our clients to offer a tailor-made solution that effectively protects operators.

ENGMAR supports its clients at every step:

- Definition of customer needs

- Tailored studies

- Project implementation

- Equipment delivery

- Training

- Equipment follow-up

Choosing ENGMAR means benefiting from personalized support for the installation and maintenance of your welding fume extraction systems. To enhance the protection of your operators, our teams are always available to assist you. Contact us to discuss your project and find the most suitable solution.

How to protect welders from Hexavalent Chromium (Chrome VI) in Welding Fumes

Read the articleIndustrial Ventilation: 3 essential principles you need to know

Read the articleDiscover our new MIG/MAG 240 extraction torch!

Read the articleWelding health and safety: U.S. regulations

Read the articleWelding health and safety: Australian regulations

Read the articleWelding health and safety: UK regulations

Read the article