In order to manage risk under the WHS Regulations 32-38, a duty holder must:

- Identify reasonably foreseeable hazards that could give rise to the risk

- Eliminate the risk so far as is reasonably practicable

- If it is not reasonably practicable to eliminate the risk – minimise the risk so far as is reasonably practicable by implementing control measures in accordance with the hierarchy of risk control

- Maintain the implemented control measure so that it remains effective

- Review, and if necessary revise all risk control measures so as to maintain, so far as is reasonably practicable, a work environment that is without risks to health and safety.

Local exhaust ventilation systems should be designed to provide a minimum capture velocity at the fume source of 0.5m/second away from the welder. Inlets and outlets should be kept clear at all times. Air from a local exhaust ventilation system should not be re-circulated into the workroom. This air should be discharged into the outside air away from other work areas and away from air conditioning inlets or compressors supplying breathing air.

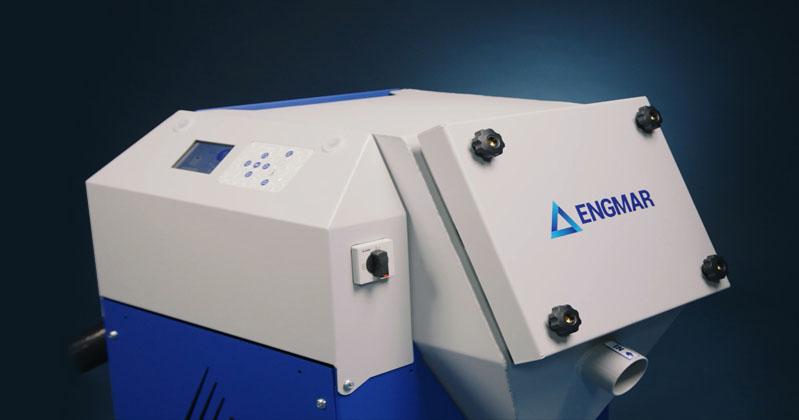

Examples of local exhaust ventilation suitable for welding operations include:

Further information: