The working conditions during welding and the layout of the workstation can negatively affect the welder's musculoskeletal system. The welder may be exposed to several risk factors. These factors depend, among other things, on the intensity of the welding, the distances to be covered at the workstation and the time frequency spent on welding operations.

In the field of welding, there are various ergonomic solutions at workstation to prevent risks of musculoskeletal disorders. Swing arms and jib cranes are among these solutions.

Swing arm Jib crane

These solutions make the welders' workstation more adapted by suspending and maintaining the equipment at height. The installation is therefore safer and more sustainable. It helps the operator to carry a load, because it reduces the weight of the torch and is more manoeuvrable.

Why using an ergonomic workstation solution?

This type of solution improves working posture while reducing the weight of the used torch during welding operations. It helps to preserve the health of welders and reduces musculoskeletal disorders.

Musculoskeletal disorders are the most common form of sick leave and the associated cost for companies is considerable (costs related to sick leave/absence, recruitment, etc.).

On the other hand, investing in an ergonomic solution at the workplace is economically beneficial and promotes a positive image of your company.

These solutions make the welders' workstation more adapted by suspending and maintaining the equipment at height. The installation is therefore safer and more sustainable. It helps the operator to carry a load, because it reduces the weight of the torch and is more manoeuvrable.

Why using an ergonomic workstation solution?

This type of solution improves working posture while reducing the weight of the used torch during welding operations. It helps to preserve the health of welders and reduces musculoskeletal disorders.

Musculoskeletal disorders are the most common form of sick leave and the associated cost for companies is considerable (costs related to sick leave/absence, recruitment, etc.).

On the other hand, investing in an ergonomic solution at the workplace is economically beneficial and promotes a positive image of your company.

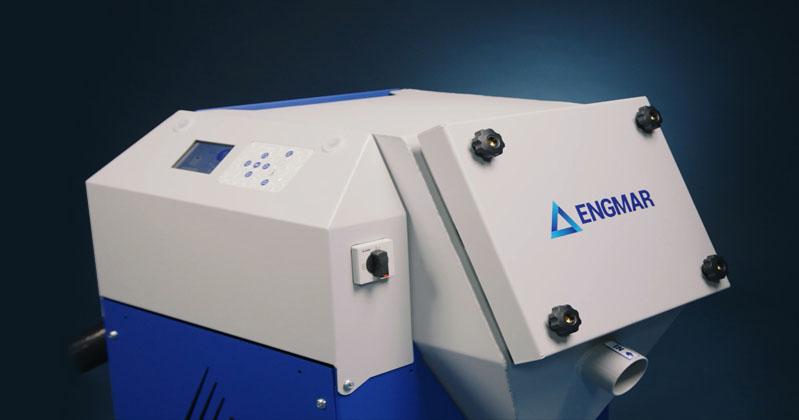

The purchase of an ergonomic solution is an investment for companies and the help of a professional in the sector is essential. ENGMAR’s teams can advise you and offer you tailor-made, turnkey solutions.

Swing arm Jib crane

These solutions make the welders' workstation more adapted by suspending and maintaining the equipment at height. The installation is therefore safer and more sustainable. It helps the operator to carry a load, because it reduces the weight of the torch and is more manoeuvrable.

Why using an ergonomic workstation solution?

This type of solution improves working posture while reducing the weight of the used torch during welding operations. It helps to preserve the health of welders and reduces musculoskeletal disorders.

Musculoskeletal disorders are the most common form of sick leave and the associated cost for companies is considerable (costs related to sick leave/absence, recruitment, etc.).

On the other hand, investing in an ergonomic solution at the workplace is economically beneficial and promotes a positive image of your company.

These solutions make the welders' workstation more adapted by suspending and maintaining the equipment at height. The installation is therefore safer and more sustainable. It helps the operator to carry a load, because it reduces the weight of the torch and is more manoeuvrable.

Why using an ergonomic workstation solution?

This type of solution improves working posture while reducing the weight of the used torch during welding operations. It helps to preserve the health of welders and reduces musculoskeletal disorders.

Musculoskeletal disorders are the most common form of sick leave and the associated cost for companies is considerable (costs related to sick leave/absence, recruitment, etc.).

On the other hand, investing in an ergonomic solution at the workplace is economically beneficial and promotes a positive image of your company.

- Healthy and motivated employees

| Jib crane | Swing arm | |

| Mobility | Fixed equipment.Smaller range of action. | Mobile equipmentA large radius of action as the balancer can be moved around the workshop. |

| Security | Safer because there is no braided hose or hose on the floor. | A little less secure because there may be a braided hose or a hose on the floor. |

| Type of wire feeder welding generators | Use with a separate wire feeder welding generator or a compact welding station. | Can be used with a separate or an integrated wire feeder generator. |

| Budget | Higher budget(3 to 4 times more expensive than a swing arm). | Lower budget(3 to 4 times less expensive than a jib crane). |