Workplace safety is an essential priority for every company. Welding activities expose operators to hazardous fumes and particles that can significantly impact health and productivity. To help employers manage these risks, leading occupational health and safety organizations such as OSHA, NIOSH, and WorkSafe provide guidance to identify, assess, and reduce exposure to welding fumes.

By following these recommendations, companies can take proactive steps to enhance worker protection and maintain compliance with international health and safety standards.

1. Identifying and Documenting Welding Fume Hazards

The first step in prevention is to assess the job site and identify all risks linked to welding fumes. This includes evaluating processes, consumables, work environments, and ventilation conditions. Documenting these hazards helps companies establish effective preventive measures and protect their workforce.

2. Four Essential Steps to Prevent Risks

Occupational safety authorities recommend a preventive approach that includes the following measures:

- Adopt low-fume welding processes whenever possible.

- Reduce the use of hazardous chemical consumables and agents.

- Capture and extract fumes directly at the source with local exhaust ventilation systems.

- Enhance air quality with general workshop ventilation.

This combination of solutions forms the basis of a proactive welding fume control strategy.

3. The Risks of Inaction

Neglecting to anticipate welding fume hazards has serious consequences for both workers and businesses:

- Health impacts including respiratory diseases and long-term illnesses.

- Production stoppages or delays due to worker absences.

- Increased operational costs from overtime or replacement hires.

- Decline in work quality when less-experienced welders cover absences.

- Work overload on remaining staff, lowering morale and efficiency.

- Loss of skills and know-how during extended workforce disruptions.

Preventive action not only safeguards health but also helps protect the company’s productivity and reputation.

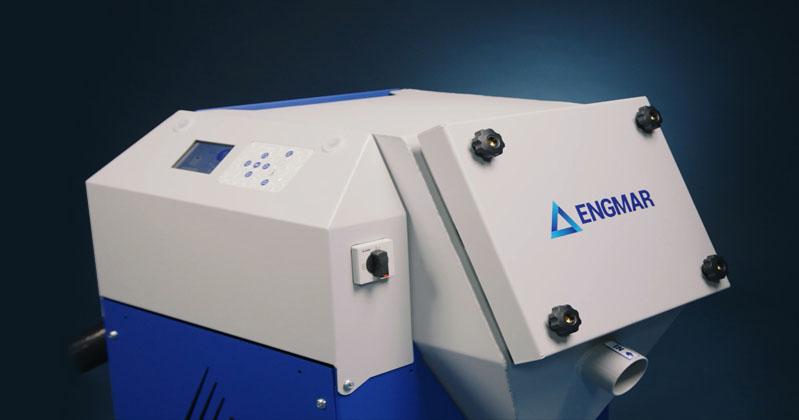

ENGMAR: Welding Fume Extraction and Ventilation Solutions

To support safer workplaces, ENGMAR designs and provides welding fume extraction systems, industrial ventilation solutions, and filtration technologies that comply with guidelines from OSHA, NIOSH, and WorkSafe.

Our team also delivers training and education for welding operators, ensuring they understand the hazards of welding fumes and can use our equipment effectively for long-term protection.