Current legislation recommend that companies prioritize alternatives to welding, or modify the welding process to reduce emissions. However, that is not always possible, and is often not sufficient. For optimal efficiency and welder protection, it is then crucial to extract welding fumes as close as possible to their source of emission, preventing them from reaching the workers’ respiratory systems.

The use of « high vacuum » solutions, such as a MIG/MAG or TIG extraction welding torch, or a extraction slit nozzle, is then made necessary. These devices prevent welding fumes from mixing with the ambient air as much as possible, thus protecting not only the welders but all other operators in the workshop as well.

In order to properly protect workers and prevent harmful particles from being be stirred up back into the ambient air, adding treatment systems for the contaminated air is also necessary. Those systems filter the dust extracted by the extraction equipment before the filtrated air is discharged and purified externally or internally.

Here is a list of welding fumes extraction devices you should prioritize depending on your needs.

1. Extraction equipments and their efficiency

Welding extraction torches

The most efficient extraction equipment is the welding extraction torch, because it extracts fumes directly at their source of emission, whatever the nature or position of the piece that needs to be welded. In order to ensure extraction is of high quality and performance, both the CARSATs and standard NF EN ISO 21904 prescribe extraction speeds to be followed in the extraction zone while they are used:

- welding extraction torch MIG/MAG < 200 Amperes = induced speed ≥ 0.25 m/s

- welding extraction torch MIG/MAG > 200 Amperes = induced speed ≥ 0.35 m/s

- welding extraction torch TIG : induced speed ≥ 0.35 m/s

When purchasing welding extraction torches, it is essential to verify that they meet the DIN EN ISO 21904 standard, which ensures optimal protection for workers as well as their health.

Extraction slit nozzles (high vacuum)

Extraction slit nozzles are particularly efficient as a result of the air flow they create opposite to the operators’ respiratory tract. They allow for welding fumes to be extracted at source, and easily fit into the workspace. The slit nozzles extract fumes accross their entire width and do not clutter up the work space, ensuring good visibility for the operator. They prove useful on workstations equipped with extraction torches and which use different welding processes.

Extraction arms

The extraction of welding fumes can also be performed using flexible extraction arms. These arms can be freely positioned and remain steady in the adjusted overhanging position. Those systems can extract welding fumes from up to around 300 – 400 mm when they are positioned correctly. A clear indication located directly on the arm should make the delimitation of this zone visible to the operator.

The extraction device must be positioned in such a way as to drive the welding fumes away from the user’s breathing zone. Making the extraction arms easy to move around is essential to making their use easier and gaining the welders’ support. A minimum speed of 0.5 m/s must be respected in the welding fumes extraction zone in order to ensure extraction is efficient. This requires regular adjustments to be made to the device as the welding process progresses.

At ENGMAR, the protection of welders and workshop operators is our main concern. We prescribe the addition of an extraction slit nozzle (low vacuum) to the extraction arms. The combination of those two pieces of equipment boosts extraction efficiency. Indeed, adding a slit nozzle at the end of an extraction arm widens the extraction flow, allowing the equipment to be positioned slightly further away from the source of the fumes. This reduces the need for the operator to change the position of the arm, making for a more comfortable and efficient work environment.

Extraction backwalls

Thanks to the partitioning of the work area, the extraction hood prevents the dilution of harmful particles into the ambient air. The dimensions and design of extraction backwalls allows them to extract welding fumes from the back of a workstation. The pivoting shutters facilitate the handling and loading of pieces and allow massive pieces to be worked on. These backwalls (extraction backwalls or extraction hoods) can be added to existing work tables or can be delivered on supporting poles. They are designed with a drawer to collect the pieces of coarse dirt that do not reach the central extraction unit’s filter. This facilitates the cleaning of the equipment. The backwalls’ extraction speed must follow the prescriptions of the INRS* and the CARSATs, set at 0.5 m/s for welding fumes.

*Practical guide for ventilation n°7 – ED668 – July 2010

Extraction tables

Extraction tables are particularly adapted when several machining processes are performed at the same work station. On these tables, the polluted air is extracted towards the bottom, and, in some cases, the back. In general, downward extraction is enough for to handle cutting processes. However, we use both extraction towards the bottom and the back of the table to extract heat-generated ascending welding fumes, ensuring they are efficiently separated from the environment.

The required airflow rate depends on the size of the extraction able. Keeping a minimal speed of 0.5 m/s in the welding zone is essential to ensure extraction efficiency is optimal. This configuration helps not only to keep operators safe but also to maintain a high air quality.

Extraction hoods

This type of extraction solution is typically used on robotized welding stations or automatic machines. Due to thermal updraft, welding fumes reach the industrial extraction hood’s detection zone. Hoods can be equipped with vertical slat shutters that reduce the influence of parasitic air currents (uncontrolled air flows, for example), thus making fume extraction more efficient. The size and shape of the extraction hood depend on the concerned work area. The airflow rate must be calculated so that the heat flow emanating from the welding point is extracted.

Extraction in ventilated cabinets

Enclosures are mainly used for welding robots in order to protect the surrounding workstations from welding fumes. Extraction is performed by equipment that is integrated to the wall, or vents located on the ceiling of the enclosure. How much air needs to be extracted depends on several factors, including the necessary recycling of air, the waiting time for the opening of the cabinet after the cycle is finished, and the speed at which welding fumes escape and spread into the ambiant air. This prevents harmful substances from spreading out of the enclosure.

2. Systems for the treatment of polluted air to use in priority

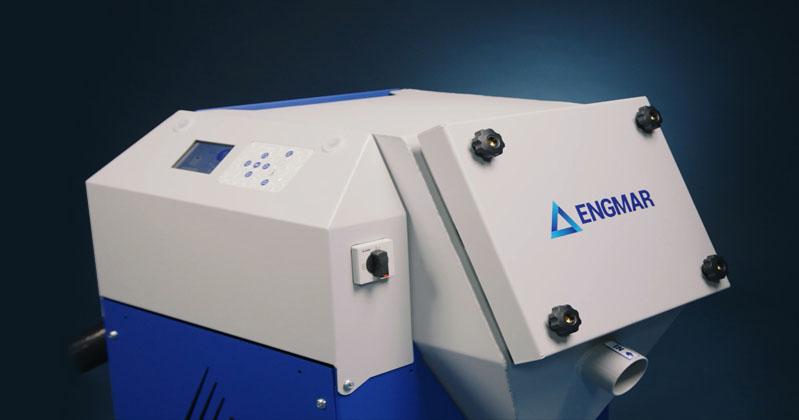

Extraction units

These industrial air extraction systems process welding fumes and evacuate them outside the factory plant using one or two extraction torches and/or extraction slit nozzles. The extraction of these fumes is optimal on each station equipped with an extraction unit, and helps to build a healthier working atmosphere. Moreover, all our options for mobile extraction units are easily integrated to the workstations, making the cluttering / efficiency ratio particularly attractive. Our extraction units, designed for the welding industry, ensure the induced speeds required by the CARSATs are reached.

High vacuum and low vacuum central extraction units

These industrial central extraction systems filter the polluted air extracted by the previously mentioned extraction equipments. Composed of decanting pre-chambers and/or filters, they purify the air before it is discharged externally (or internally if an exemption can be granted by the CARSAT). Such systems can be equipped with fire and explosion suppression systems tailored to your needs.

Industrial central extraction units can be installed on the inside or on the outside and allow several air-extracting devices to work simulteanously (torch, slit nozzle, extraction arm…). They can be resized to meet your needs and demands.

General ventilation

An industrial general ventilation system may complete the previously mentioned extraction systems. It plays an essential role in reducing the concentration of harmful substances that weren’t picked up by the extraction systems, thereby protecting the surrounding workstations. Air is usually extracted at a height of 4 to 6 meters, while fresh air is introduced at ground level. This process helps with air recycling, and ensures air is filtered several times every hour. Integrating a general ventilation system to extaction installations not only increases air quality, but also contributes to creating a safer, healthier work environment.

It is possible to couple an industrial ventilation system with a central air treatment unit. The fresh air brought in by the ventilation system is first heated up to a comfortable degree inside the building, while the extracted air is discharged outside. The latter, though its energy level is higher than that of the fresh air found outside, is evacuated to ensure air quality is optimal. The main objective of the central air treatment unit is to transfer the heat from the extracted air to the fresh air. This process not only makes the work environment more comfortable for operators, but also allows for significant savings to be made on the heating budget for ventilation air.

By optimizing the transfer of heat, the amount of energy needed to heat up the fresh air is reduced, making energy management more efficient and durable. This heat collection system is essential to maximize the energy efficiency of modern buildings, while ensuring the inside is comfortable to work in.

3. Choosing the right extraction solution

In order to ensure the security and safety of your workers, it is essential to choose the right extraction equipment. Our sales engineers specialized in welding and industrial extraction will visit your factory plants in order to exchange with your teams and conduct an audit.

Contact us if you want to set up a free consultation, and learn about how our solutions can satisfy even the most specific of your demands.